Our Smart Solutions

Advanced Automation & Control Solutions

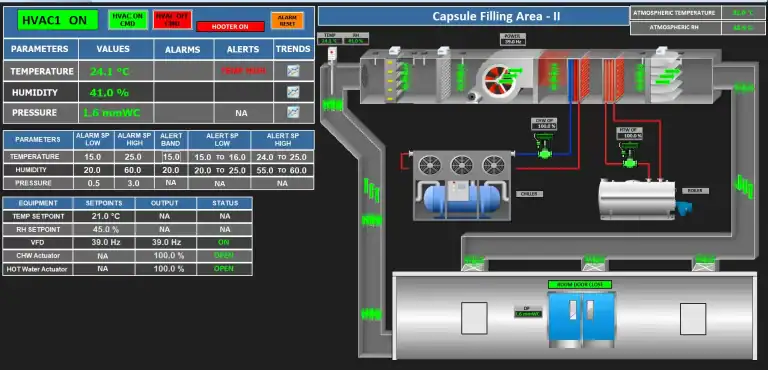

End-to-end automation solutions using PLC, HMI, and SCADA systems tailored to process, utility, and packaging lines.

Logic development for batch operations, sequencing, interlocks, alarms, and real-time control responses.

Multi-brand PLC support including Siemens, Allen Bradley, Delta, Omron, and Schneider based on application needs.

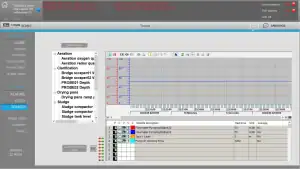

SCADA systems designed with historical trending, alarm/event logs, multi-user access, and intuitive dashboards.

Centralized control with data acquisition from sensors, VFDs, and field devices via Modbus, Profibus, or Ethernet/IP.

Automation of HVAC, AHUs, WTP, compressors, and manufacturing lines to improve efficiency and reduce manual errors.

Integration with MES, BMS, and ERP systems for seamless data flow and centralized operational visibility.

Designed for pharma-grade environments with features supporting 21 CFR Part 11, validation, and audit trail compliance.

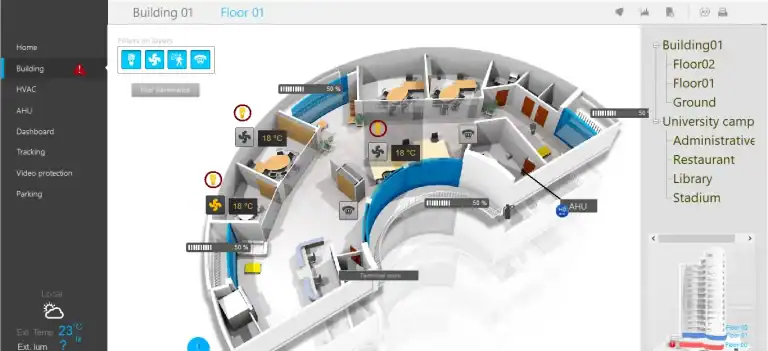

Smart HVAC & BMS for Cleanroom and Process Industries

Centralized automation of AHUs, FCUs, VAVs, exhaust systems, chillers, and cleanroom HVAC zones.

Integration of temperature, RH, DP, CO₂ sensors, and actuators for accurate PID-based environmental control.

PLC/SCADA-based logic for auto control, night setback, filter status, damper position, and alarm handling.

BMS platforms with centralized monitoring, scheduling, and multi-zone energy optimization.

Supports BACnet, Modbus, and Ethernet protocols for seamless integration with third-party systems.

Interface with VFDs for pressure and airflow control, improving efficiency and extending equipment life.

Real-time dashboards, alarms, trend logs, and auto-reporting for validation and audit readiness.

Ideal for pharma cleanrooms, R&D labs, warehouses, and GMP-classified HVAC operations.

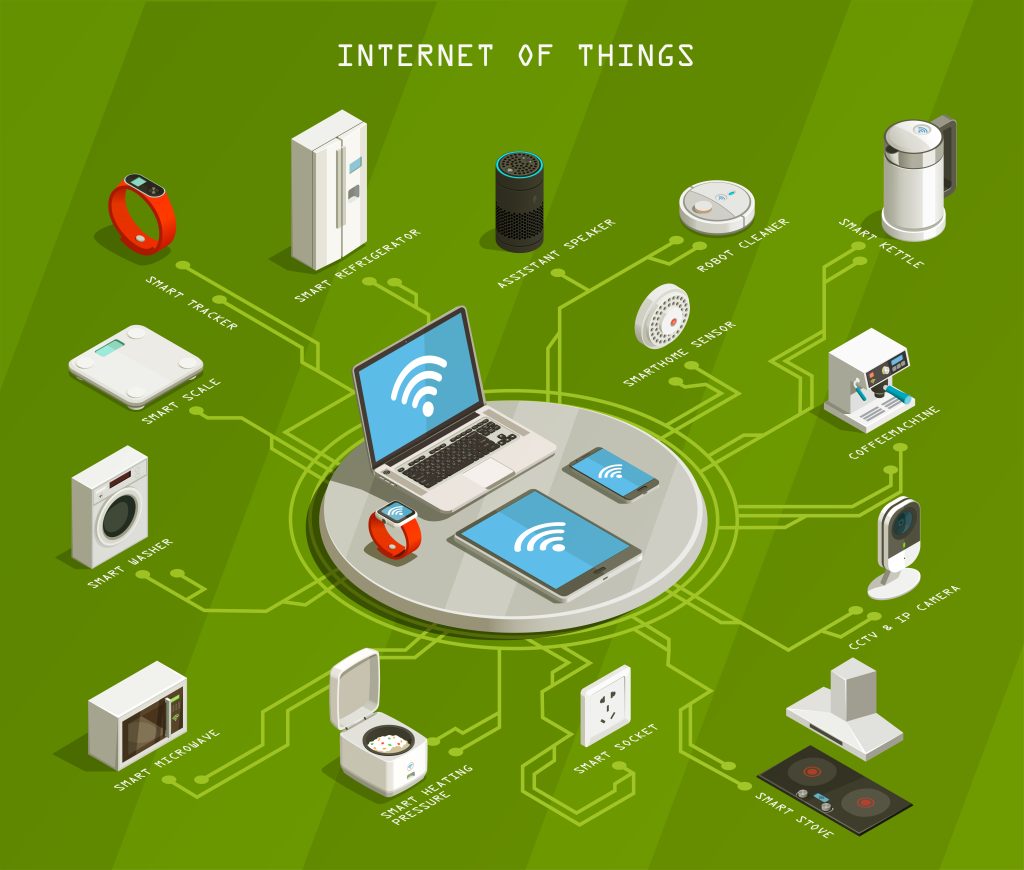

Digital Transformation & Industrial IoT Solutions

IoT-enabled systems for real-time monitoring of process, utility, and facility data across multiple plant locations.

Integration of smart sensors, energy meters, gateways, and cloud platforms for end-to-end data flow.

Wireless and wired connectivity using MQTT, Modbus TCP, OPC-UA, and REST APIs for seamless device communication.

Cloud dashboards with mobile/web access for live KPIs, alerts, analytics, and remote diagnostics.

Smart alerts for parameter deviations, machine downtime, energy waste, and predictive maintenance triggers.

Centralized data logging, batch reports, and audit trails stored securely on cloud or local servers.

Scalable architecture supporting edge computing, third-party device integration, and multi-site expansion.

Ideal for pharma utilities, cleanrooms, WTP, STP, HVAC, and equipment performance tracking in regulated environments.

Sustainable Energy & Efficiency Solutions

Smart energy monitoring systems to track real-time power consumption, load profiles, and efficiency trends.

Integration of energy meters, analyzers, and IoT gateways for live kWh, PF, demand, and harmonics data.

VFD retrofitting for pumps, blowers, and compressors to reduce energy usage and improve motor control.

Power factor correction panels with APFC relays and capacitor banks for penalty avoidance and grid stability.

Load optimization through time-of-use scheduling, auto load shedding, and process sequencing.

Data-driven energy audits with actionable reports for reducing electrical losses and peak load trimming.

SCADA/BMS integration for centralized energy visualization, alarms, and automatic response mechanisms.

Aligned with pharma energy compliance, ESG goals, and green building certifications (LEED/GMP+).

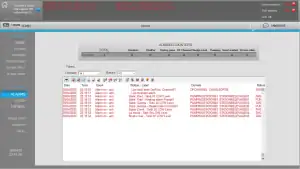

Data Logging & Audit Trail

Centralized logging of process, utility, HVAC, and equipment data with real-time and historical access.

21 CFR Part 11 compliant systems with secure user login, role-based access, and electronic signatures.

Audit trail features capturing changes, timestamps, user actions, and system events automatically.

Integration with PLC, SCADA, BMS, and IoT devices for seamless data acquisition and logging.

Auto-generation of batch reports, trend graphs, alarm logs, and deviation summaries.

Tamper-proof data storage on local servers or cloud with backup and disaster recovery options.

Filterable data views for QA, validation, and regulatory audits with export to PDF/Excel.

Essential for pharma cleanrooms, HVAC zones, utility tracking, and compliance-critical environments.

Next-Gen MES Integration

Integration of Manufacturing Execution Systems (MES) with PLC, SCADA, BMS, and ERP for end-to-end process visibility.

Real-time tracking of batches, equipment status, user actions, and production parameters.

Support for eBMR (Electronic Batch Manufacturing Records) with version control and compliance checks.

Automated data flow from field devices to MES using OPC, API, and middleware connectors.

21 CFR Part 11 readiness with audit trails, user authentication, e-signatures, and exception handling.

Custom dashboards for operations, QA, and management with KPIs, OEE, downtime, and alerts.

Integration with Pas-X, PharmaSuite, or custom MES platforms for pharma-specific workflows.

Enhances traceability, reduces manual errors, and ensures compliance with GMP and regulatory standards.