Our Products

Electrical Control Panels

Custom-built panels for LT distribution, motor control, automation, and utility applications across industries.

Designs based on IEC 61439-1 and IS standards with SLDs, GA layouts, and thermal derating calculations.

Fabricated with powder-coated CRCA enclosures in IP42–IP65 ratings, wall-mounted or floor-standing types.

Integrated with MCCBs, ACBs, contactors, relays, energy meters, and indication systems.

Internal wiring with color-coded flexible copper cables, ferruling, labeling, and channel routing for GMP compliance.

Panels tested for insulation resistance, phase sequencing, interlocks, and operational simulation before dispatch.

Smart-ready configurations with energy monitoring, load balancing, and fieldbus communication (Modbus, Profibus, Ethernet).

Suitable for pharma, food, chemical, utility, packaging, and process industries requiring safe and stable power distribution.

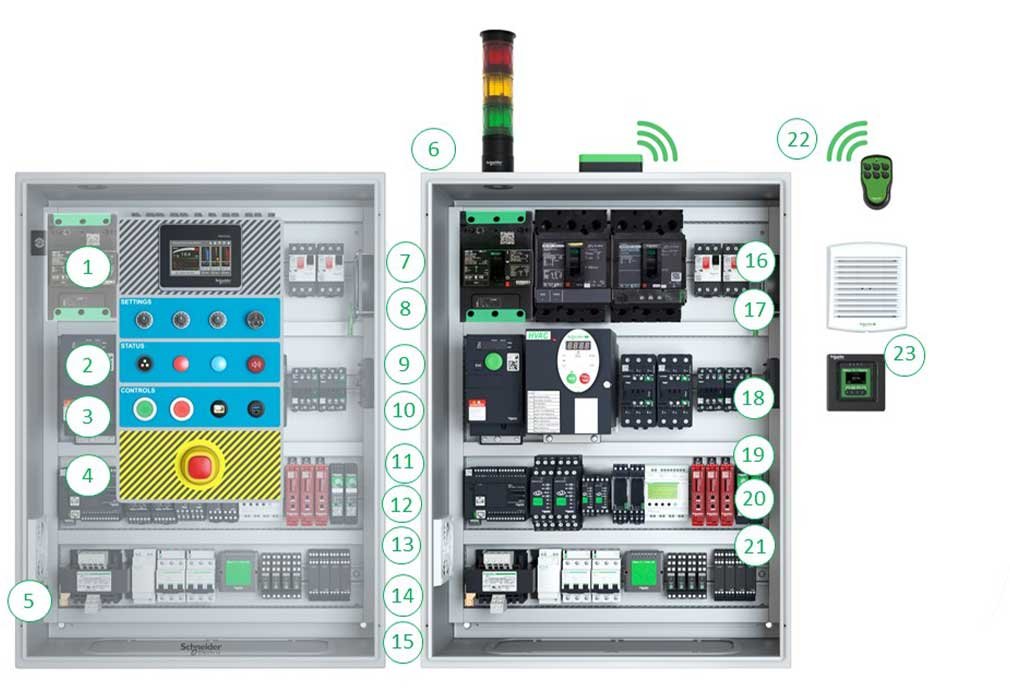

BMS & HVAC Panels

Purpose-built panels for controlling AHUs, FCUs, VAVs, exhaust systems, chillers, and utility HVAC equipment.

Designed with PID control loops, timers, digital/analog inputs & outputs, and sensor feedback integration.

Equipped with PLC, microcontroller, or relay-based logic depending on application scale and complexity.

Supports BACnet, Modbus, and Ethernet communication for seamless BMS/SCADA integration.

Built with actuators, pressure/temperature/RH sensors, motor starters, dampers, and HMI interfaces.

IP-rated enclosures, with phase monitoring, auto/manual modes, interlocks, and alarm systems.

Energy-efficient design supporting occupancy-based control, scheduling, and zone-wise automation.

Widely used in pharma cleanrooms, R&D labs, production areas, and HVAC control rooms for compliance and efficiency.

PCC & Utility Panel

Centralized LT power distribution panels designed to handle high current loads for plant-wide applications.

Engineered with ACBs, MCCBs, CTs, energy meters, phase selectors, and protection relays as per IEC/IS standards.

Busbar sizing with fault withstand capacity, short circuit calculation, and temperature rise validation.

Intelligent metering for voltage, current, kWh, power factor, demand, and load monitoring.

Internal segregation for incomers, bus couplers, feeders, and metered outputs with safety interlocks.

IP42–IP65 enclosures with front/rear access, indicator systems, earthing, and gland plate provisions.

SCADA/BMS-ready with Modbus/Ethernet integration for remote diagnostics and energy audits.

Widely deployed in utilities, HVAC mains, compressors, chillers, boilers, and critical power systems in pharma and industrial plants.

VFD & Starter Panels

Designed for precise motor speed control, soft starting, and energy optimization in various industrial processes.

Configured with VFDs, soft starters, DOL, and Star-Delta starters based on motor rating and application.

Supports pump, blower, and HVAC motor control with overload protection, bypass, and auto/manual modes.

Integrated with PID controllers, analog feedback (pressure, flow, temperature), and safety interlocks.

Enclosures built to IP42–IP65 with proper heat dissipation, cable management, and fault indication systems.

Communication-enabled VFDs with Modbus, Profibus, or Ethernet for SCADA/BMS connectivity.

Suitable for pharma utilities, HVAC systems, water treatment plants, and process control lines.

Factory-tested for acceleration/deceleration profiles, torque limits, fault responses, and safe shutdown.

PLC & SCADA Panels

Designed for centralized or distributed automation control with leading PLC platforms like Siemens, Allen Bradley, Delta, and Schneider.

Configured with digital/analog IO modules, CPU, communication cards, power supplies, and expandable architecture.

Integrated with touchscreen HMIs, pushbuttons, alarms, and status indicators for real-time local operation.

SCADA panels equipped with industrial PCs, data acquisition modules, protocol converters, and network switches.

Supports multi-protocol communication (Modbus, Profibus, Ethernet/IP, OPC-UA) for BMS, DCS, and MES connectivity.

Structured wiring with IO labeling, ferruling, shielded signal cabling, and grounding for EMI protection.

Designed for pharma-grade automation with 21 CFR Part 11 features like audit trail, e-signature, and access control.

Used in process automation, cleanroom control, HVAC systems, utility monitoring, and production line management.

MCC & IMCC Panels

Intelligent Motor Control Centers (IMCC) designed with advanced starters, VFDs, soft starters, and motor protection relays.

Built-in diagnostics, status monitoring, fault indication, and trip history for predictive maintenance and safety.

Modular design with feeder, control, and communication compartments ensuring easy scalability and segregation.

Equipped with smart MCCBs, contactors, motor relays, and energy meters integrated with PLC or DCS networks.

Supports communication over Modbus, Profibus, Ethernet/IP, and integration with SCADA, DCS, and MES systems.

Panels designed to handle multi-motor control with interlocking, sequential start logic, and load shedding.

DCS-ready architecture for distributed IOs, remote terminal units, and centralized plant monitoring/control.

Widely used in pharma utilities, HVAC systems, process equipment, WTP/ETP plants, and cleanroom automation.